Manufacturing in Space

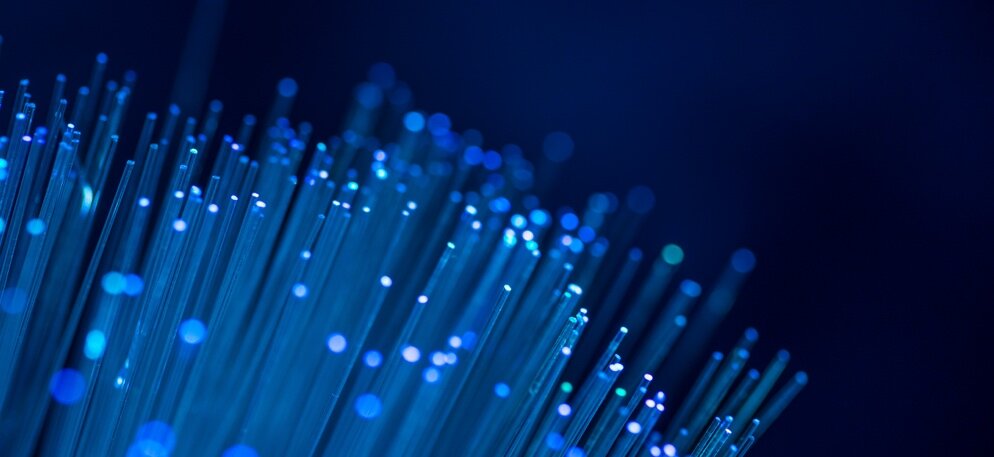

Fiber Optics

The world of materials science research in microgravity brings many opportunities for teams that are developing products for earth and space. Fiber optic development is one of those products.

One of the first forms of connecting communities was copper wire for the transmission of electrical signals from one point to another. Copper wire led to the use of telegraphs for transmitting rough information (data), and eventually phones for voice communication.

Much as copper lines provided the foundation of the Information Age in the 19th and 20th centuries, fiber optic cables have become a staple of communication in the 21st century. Fiber offers orders of magnitude more information density when compared to copper, and even transmission of radio or optical communications through air. However, optical fiber is still limited by the physics of light and diffraction. To help overcome some limitations in the mid-IR wavelengths and attenuation, fluoride has been integrated into the formulation of optical fiber and is termed heavy metal fluoride glass (HMFG). Due to the low viscosity of fluoride, manufacturing is difficult and often results in crystallization that causes scattering and attenuation of light.

Because of the difficulty in manufacturing HMFG terrestrially, costs are significant. Manufacturing in an environment where gravitational effects are removed enables manufacturers to overcome the effects of viscosity and therefore the negative effects of crystallization.